U-1000 ARVFV Cable

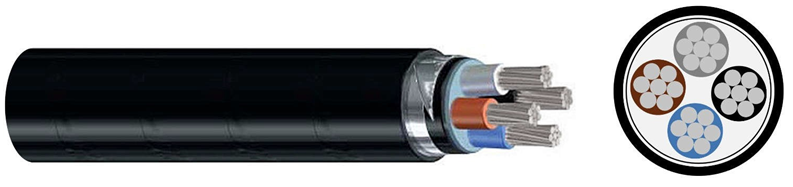

Power cable 0,6/1 kV with AL conductors, XLPE insulated and Double Steel Tape Armoured

Voltage Rating: 600/1000 Volts

Conductor: Aluminum conductor

Insulation: Cross-linked polyethylene (XLPE)

Out sheath: PVC

Armour: Double Galvansied Steel Tape

U-1000 ARVFV Industrial Cable Application

The U-1000 ARVFV armoured aluminium cables can be used in all low voltage power installations. This product is used in photovoltaic applications. These cables are suitable for direct burial without additional protection , for installation on cable trays or in conducts where mechanical protection is necessary.

U-1000 ARVFV Industrial Cable Standard:

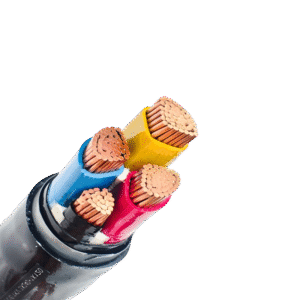

U-1000 ARVFV Industrial Cable Construction

Conductor: Aluminum conductor,Strands to IEC 60228 class 2

Insulation: Cross-linked polyethylene (XLPE) insulation type XLPE according to IEC 60502-1.

Armour: Double steel or aluminium tape armour. Aluminium armour is used in single-core cables to avoid parasite currents that may overheat the cable. Steel tape is used in the multicore cables.

Outer sheath: Flexible PVC outer sheath, Black colour.

The standard identification of insulated conductors is the following:

U-1000 ARVFV Industrial Cable Characteristics

| Cross Section | Insulation thickness | Amour thickness | Minimum Sheath thickness | Maximum Overall diameter | Approx Cable weight |

| mm^2 | mm | mm | mm | mm | kg/km |

| 2×10 | 0.7 | 0.2 | 1.4 | 18.5 | 420 |

| 2×16 | 0.7 | 0.2 | 1.5 | 20.5 | 540 |

| 2×25 | 0.9 | 0.2 | 1.6 | 24.5 | 760 |

| 2×35 | 0.9 | 0.2 | 1.7 | 27 | 930 |

| 3×10 | 0.7 | 0.2 | 1.5 | 19 | 470 |

| 3×16 | 0.7 | 0.2 | 1.5 | 22 | 590 |

| 3×25 | 0.9 | 0.2 | 1.6 | 26 | 830 |

| 3×35 | 0.9 | 0.2 | 1.7 | 29 | 1030 |

| 3×50 | 0.9 | 0.2 | 1.8 | 32.5 | 1290 |

| 3×70 | 1.1 | 0.2 | 2 | 37.5 | 1710 |

| 3×95 | 1.1 | 0.5 | 2.1 | 43.5 | 2610 |

| 3×120 | 1.2 | 0.5 | 2.3 | 47.5 | 3110 |

| 3×150 | 1.4 | 0.5 | 2.4 | 53 | 3770 |

| 3×185 | 1.6 | 0.5 | 2.5 | 58 | 4540 |

| 3×240 | 1.7 | 0.5 | 2.7 | 65.5 | 5620 |

| 3×300 | 1.8 | 0.5 | 2.9 | 72 | 6830 |

| 3×50+35 | 1.0/09 | 0.2 | 1.9 | 34.5 | 1500 |

| 3×70+50 | 1.1/0.9 | 0.2 | 2 | 40 | 2000 |

| 3×95+50 | 1.1/1.0 | 0.5 | 2.2 | 45 | 2870 |

| 3×120+70 | 1.2/1.1 | 0.5 | 2.3 | 50 | 3460 |

| 3×150+70 | 1.4/1.1 | 0.5 | 2.5 | 54 | 4090 |

| 3×185+70 | 1.6/1.1 | 0.5 | 2.6 | 59 | 4980 |

| 3×240+95 | 1.7/1.1 | 0.5 | 2.8 | 66 | 6210 |

| 4×10 | 0.7 | 0.2 | 1.5 | 20.5 | 540 |

| 4×16 | 0.7 | 0.2 | 1.6 | 23.5 | 700 |

| 4×25 | 0.9 | 0.2 | 1.7 | 28 | 1000 |

| 4×35 | 0.9 | 0.2 | 1.8 | 31.5 | 1230 |

| 4×50 | 1 | 0.2 | 1.9 | 35.5 | 1550 |

| 4×70 | 1.1 | 0.5 | 2.1 | 42.5 | 2490 |

| 4×95 | 1.1 | 0.5 | 2.3 | 47.5 | 3120 |

| 4×120 | 1.2 | 0.5 | 2.4 | 53 | 3780 |

| 4×150 | 1.4 | 0.5 | 2.6 | 58.5 | 4550 |

| 4×185 | 1.6 | 0.5 | 2.7 | 64.5 | 5490 |

| 4×240 | 1.7 | 0.5 | 2.9 | 72.5 | 6860 |

| 4×300 | 1.8 | 0.5 | 3.1 | 79.5 | 8250 |

| 5×10 | 0.7 | 0.2 | 1.6 | 22.5 | 640 |

YOU MAY LIKE

Related products

-

Steel Tape Armoured Cable Type

YJV22 Cable

-

Steel Tape Armoured Cable Type

RVFAV-K Cable

-

Steel Tape Armoured Cable Type

X1AV Cable

-

Steel Tape Armoured Cable Type

LXAV Cable

-

Steel Tape Armoured Cable Type

LVAV Cable

-

Steel Tape Armoured Cable Type

N2XBH Cable

-

Steel Tape Armoured Cable Type

ACYAbY ACYAbY-F Cable

-

Steel Tape Armoured Cable Type

N2XB2Y Cable