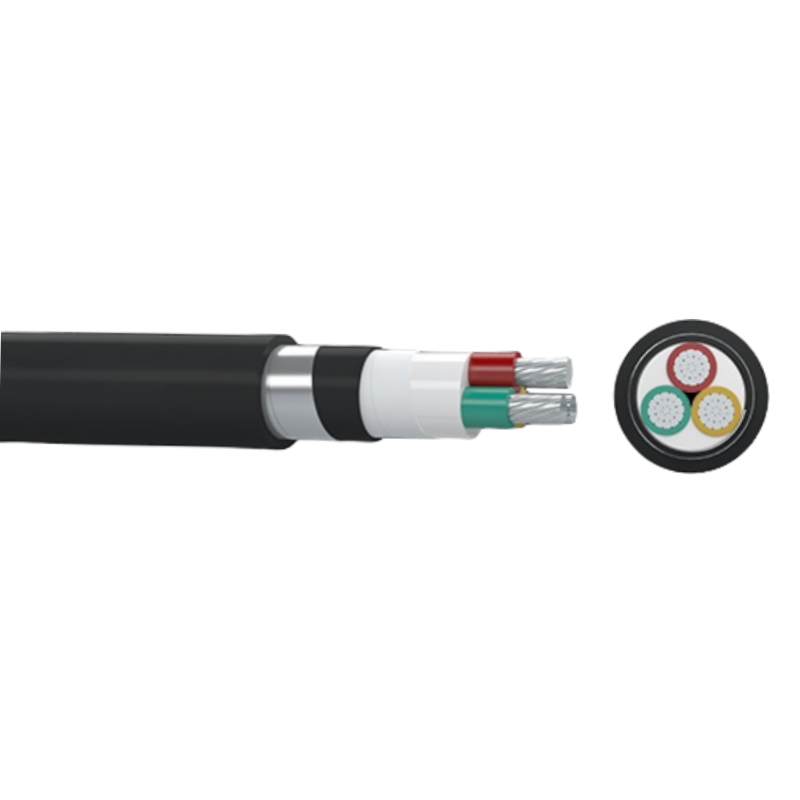

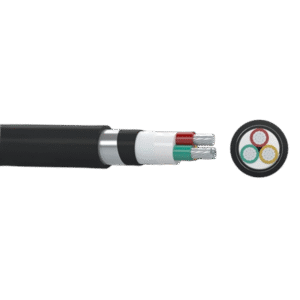

NAYBY – VLV62 VLV22(铝/PVC/PVC/DSTA/PVC)

These power cables are used for electricity supply in low voltage installation systems. They are well adapted to underground use in industrial applications with an additional mechanical protection. These cables can be laying indoor, tunnel and underground. Able to bear external mechanical force, but unable to bear large pulling force.

Application

The Gongniu Cable NAYBY – VLV62 power cable is designed for versatile use in low-voltage power distribution networks. You can install it indoors or outdoors, in both dry and damp conditions. It is ideal for critical applications like switchgear, power stations, and a wide range of industrial settings. This cable excels in harsh environments where high mechanical protection is essential for safety and operational continuity. It can also be safely installed in cable channels or buried underground with appropriate additional protection.

Description

Our NAYBY – VLV62 cable features a stranded aluminum conductor, providing cost-effective power transmission. It uses high-quality PVC for both its insulation and the outer sheath. A double layer of galvanized steel tape forms the armor, providing superior mechanical protection. This design adds strength without significantly increasing the cable’s weight or overall diameter. The PVC outer sheath offers excellent resistance to environmental factors, including UV radiation, and is flame retardant for enhanced safety. The cable is rated for 0.6/1kV voltage. It operates effectively up to a maximum temperature of +70°C and can withstand short-circuit temperatures up to +160°C. Core identification follows standard color codes: Brown and Blue for 2-core cables; Brown, Blue, and Green/Yellow for 3-core cables; and Brown, Black, Grey, and Green/Yellow for 4-core cables. For 5-core cables, the colors are Brown, Blue, Black, Grey, and Green/Yellow.

Specification

The Gongniu Cable NAYBY – VLV62 cable is manufactured to comply with leading international standards, including IEC 60502-1 and DIN VDE 0276-603. Its flame retardancy adheres to IEC 60332-1. This cable also meets the requirements of the Construction Products Regulation (CPR) EN 50575, ensuring its suitability for use in Europe. Detailed electrical characteristics, including current carrying capacity and conductor resistance, are available in our comprehensive technical datasheets. Specific dimensions and weights for various core configurations and nominal cross-sectional areas are also provided in our product documentation.

Technical Parameter

| No. of Cores and Nominal Cross Section | Min. Number of Wires | Nominal Insulation Thickness | Nominal Steel Tape Thickness | Nominal Sheath Thickness | Approx. Overall Diameter | Approx. Weight | Max. D.C. Resistance of Conductor at 20℃ |

| No. × mm² | No. | mm | mm | mm | mm | kg/km | Ω/km |

| 2×2.5 | 1 | 0.8 | 0.2 | 1.8 | 13.4 | 246 | 12.1 |

| 2×4 | 1 | 1.0 | 0.2 | 1.8 | 15.2 | 306 | 7.41 |

| 2×6 | 1 | 1.0 | 0.2 | 1.8 | 16.2 | 350 | 4.61 |

| 2×10 | 6 | 1.0 | 0.2 | 1.8 | 18.7 | 429 | 3.08 |

| 2×16 | 6 | 1.0 | 0.2 | 1.8 | 20.3 | 522 | 1.91 |

| 2×25 | 6 | 1.2 | 0.2 | 1.8 | 23.5 | 684 | 1.20 |

| 2×35 | 6 | 1.2 | 0.2 | 1.8 | 25.5 | 804 | 0.868 |

| 2×50 | 6 | 1.4 | 0.2 | 1.8 | 28.9 | 990 | 0.641 |

| 2×70 | 12 | 1.4 | 0.2 | 1.9 | 32.8 | 1261 | 0.443 |

| 2×95 | 15 | 1.6 | 0.5 | 2.1 | 38.8 | 1990 | 0.320 |

| 2×120 | 15 | 1.6 | 0.5 | 2.2 | 41.8 | 2262 | 0.253 |

| 2×150 | 15 | 1.8 | 0.5 | 2.4 | 46.4 | 2741 | 0.206 |

| 2×185 | 30 | 2.0 | 0.5 | 2.5 | 50.6 | 3221 | 0.164 |

| 2×240 | 30 | 2.2 | 0.5 | 2.7 | 56.4 | 3945 | 0.125 |

| 2×300 | 30 | 2.4 | 0.5 | 2.9 | 62.4 | 4758 | 0.100 |

| 2×400 | 53 | 2.6 | 0.5 | 3.1 | 69.2 | 5756 | 0.0778 |

| 3×2.5 | 1 | 0.8 | 0.2 | 1.8 | 14.0 | 271 | 12.1 |

| 3×4 | 1 | 1.0 | 0.2 | 1.8 | 15.8 | 343 | 7.41 |

| 3×6 | 1 | 1.0 | 0.2 | 1.8 | 16.9 | 396 | 4.61 |

| 3×10 | 6 | 1.0 | 0.2 | 1.8 | 19.7 | 491 | 3.08 |

| 3×16 | 6 | 1.0 | 0.2 | 1.8 | 21.4 | 607 | 1.91 |

| 3×25 | 6 | 1.2 | 0.2 | 1.8 | 24.8 | 808 | 1.20 |

| 3X35 | 6 | 1.2 | 0.2 | 1.8 | 27.0 | 960 | 0.868 |

| 3×50 | 6 | 1.4 | 0.2 | 1.9 | 30.9 | 1208 | 0.641 |

| 3×70 | 12 | 1.4 | 0.2 | 2.0 | 35.0 | 1555 | 0.443 |

| 3×95 | 15 | 1.6 | 0.5 | 2.2 | 41.4 | 2409 | 0.320 |

| No. of Cores and Nominal Cross Section | Min. Number of Wires | Nominal Insulation Thickness | Nominal Steel Tape Thickness | Nominal Sheath Thickness | Approx. Overall Diameter | Approx. Weight | Max. D.C. Resistance of Conductor at 20℃ |

| No. × mm² | No. | mm | mm | mm | mm | kg/km | Ω/km |

| 3×120 | 15 | 1.6 | 0.5 | 2.3 | 44.6 | 2758 | 0.253 |

| 3×150 | 15 | 1.8 | 0.5 | 2.5 | 49.5 | 3348 | 0.206 |

| 3×185 | 30 | 2.0 | 0.5 | 2.6 | 54.0 | 3963 | 0.164 |

| 3×240 | 30 | 2.2 | 0.5 | 2.8 | 60.6 | 4957 | 0.125 |

| 3×300 | 30 | 2.4 | 0.5 | 3.0 | 66.7 | 5925 | 0.100 |

| 3×400 | 53 | 2.6 | 0.5 | 3.3 | 74.6 | 7329 | 0.0778 |

| 4×2.5 | 1 | 0.8 | 0.2 | 1.8 | 14.8 | 307 | 12.1 |

| 4×4 | 1 | 1.0 | 0.2 | 1.8 | 16.9 | 394 | 7.41 |

| 4×6 | 1 | 1.0 | 0.2 | 1.8 | 18.2 | 458 | 4.61 |

| 4×10 | 6 | 1.0 | 0.2 | 1.8 | 21.2 | 573 | 3.08 |

| 4×16 | 6 | 1.0 | 0.2 | 1.8 | 23.2 | 717 | 1.91 |

| 4×25 | 6 | 1.2 | 0.2 | 1.8 | 27.0 | 965 | 1.20 |

| 4×35 | 6 | 1.2 | 0.2 | 1.9 | 29.6 | 1169 | 0.868 |

| 4×50 | 6 | 1.4 | 0.2 | 2.0 | 34.7 | 1527 | 0.641 |

| 4×70 | 12 | 1.4 | 0.5 | 2.2 | 39.9 | 2302 | 0.443 |

| 4×95 | 15 | 1.6 | 0.5 | 2.4 | 46.0 | 2987 | 0.320 |

| 4×120 | 15 | 1.6 | 0.5 | 2.5 | 49.6 | 3430 | 0.253 |

| 4×150 | 15 | 1.8 | 0.5 | 2.6 | 54.4 | 4086 | 0.206 |

| 4×185 | 30 | 2.0 | 0.5 | 2.8 | 60.0 | 4950 | 0.164 |

| 4×240 | 30 | 2.2 | 0.5 | 3.0 | 67.0 | 6129 | 0.125 |

| 4×300 | 30 | 2.4 | 0.5 | 3.2 | 74.1 | 7430 | 0.100 |

| 4×400 | 53 | 2.6 | 0.5 | 3.5 | 82.4 | 9112 | 0.0778 |

| 5×2.5 | 1 | 0.8 | 0.2 | 1.8 | 15.8 | 345 | 12.1 |

| 5×4 | 1 | 1.0 | 0.2 | 1.8 | 18.1 | 447 | 7.41 |

| 5×6 | 1 | 1.0 | 0.2 | 1.8 | 19.5 | 524 | 4.61 |

| 5×10 | 6 | 1.0 | 0.2 | 1.8 | 22.9 | 662 | 3.08 |

| 5×16 | 6 | 1.0 | 0.2 | 1.8 | 25.1 | 834 | 1.91 |

| 5×25 | 6 | 1.2 | 0.2 | 1.9 | 29.6 | 1147 | 1.20 |

| 5×35 | 6 | 1.2 | 0.2 | 1.9 | 33.0 | 1426 | 0.868 |

| 5×50 | 6 | 1.4 | 0.5 | 2.2 | 39.4 | 2202 | 0.641 |

| No. of Cores and Nominal Cross Section | Min. Number of Wires | Nominal Insulation Thickness | Nominal Steel Tape Thickness | Nominal Sheath Thickness | Approx. Overall Diameter | Approx. Weight | Max. D.C. Resistance of Conductor at 20℃ |

| No. × mm² | No. | mm | mm | mm | mm | kg/km | Ω/km |

| 5×70 | 12 | 1.4 | 0.5 | 2.3 | 43.6 | 2719 | 0.443 |

| 5×95 | 15 | 1.6 | 0.5 | 2.5 | 50.4 | 3539 | 0.320 |

| 5×120 | 15 | 1.6 | 0.5 | 2.6 | 54.3 | 4077 | 0.253 |

| 5×150 | 15 | 1.8 | 0.5 | 2.8 | 60.3 | 4963 | 0.206 |

| 5×185 | 30 | 2.0 | 0.5 | 3.0 | 66.1 | 5940 | 0.164 |

| 5×240 | 30 | 2.2 | 0.5 | 3.2 | 74.2 | 7455 | 0.125 |

| 5×300 | 30 | 2.4 | 0.5 | 3.5 | 81.8 | 8990 | 0.100 |

| 5×400 | 53 | 2.6 | 0.8 | 3.8 | 92.2 | 11931 | 0.0778 |

| 3×4+1×2.5 | 1/1 | 1.0/0.8 | 0.2 | 1.8 | 16.4 | 371 | 7.41/12.1 |

| 3×6+1×4 | 1/1 | 1.0/1.0 | 0.2 | 1.8 | 17.9 | 442 | 4.61/7.41 |

| 3×10+1×6 | 6/1 | 1.0/1.0 | 0.2 | 1.8 | 20.5 | 544 | 3.08/4.61 |

| 3×16+1×10 | 6/6 | 1.0/1.0 | 0.2 | 1.8 | 22.7 | 680 | 1.91/3.08 |

| 3×25+1×16 | 6/6 | 1.2/1.0 | 0.2 | 1.8 | 26.1 | 901 | 1.20/1.91 |

| 3×35+1×16 | 6/6 | 1.2/1.0 | 0.2 | 1.8 | 27.9 | 1042 | 0.868/1.91 |

| 3×50+1×25 | 6/6 | 1.4/1.2 | 0.2 | 1.9 | 32.8 | 1373 | 0.641/1.20 |

| 3×70+1×35 | 12/6 | 1.4/1.2 | 0.2 | 2.1 | 36.6 | 1735 | 0.443/0.868 |

| 3×95+1×50 | 15/6 | 1.6/1.4 | 0.5 | 2.3 | 43.2 | 2657 | 0.320/0.641 |

| 3×120+1×70 | 15/12 | 1.6/1.4 | 0.5 | 2.4 | 47.2 | 3145 | 0.253/0.443 |

| 3×150+1×70 | 15/12 | 1.8/1.4 | 0.5 | 2.5 | 50.9 | 3633 | 0.206/0.443 |

| 3×185+1×95 | 30/15 | 2.0/1.6 | 0.5 | 2.7 | 56.2 | 4395 | 0.164/0.320 |

| 3×240+1×120 | 30/15 | 2.2/1.6 | 0.5 | 2.9 | 62.8 | 5449 | 0.125/0.253 |

| 3×300+1×150 | 30/15 | 2.4/1.8 | 0.5 | 3.1 | 69.1 | 6536 | 0.100/0.206 |

| 3×400+1×185 | 53/30 | 2.6/2.0 | 0.5 | 3.3 | 76.9 | 8039 | 0.0778/0.164 |

| 3×4+2×2.5 | 1/1 | 1.0/0.8 | 0.2 | 1.8 | 17.2 | 406 | 7.41/12.1 |

| 3×6+2×4 | 1/1 | 1.0/1.0 | 0.2 | 1.8 | 18.9 | 493 | 4.61/7.41 |

| 3×10+2×6 | 6/1 | 1.0/1.0 | 0.2 | 1.8 | 21.5 | 606 | 3.08/4.61 |

| 3×16+2×10 | 6/6 | 1.0/1.0 | 0.2 | 1.8 | 24.2 | 764 | 1.91/3.08 |

| 3×25+2×16 | 6/6 | 1.2/1.0 | 0.2 | 1.8 | 27.7 | 1011 | 1.20/1.91 |

| 3×35+2×16 | 6/6 | 1.2/1.0 | 0.2 | 1.9 | 29.5 | 1159 | 0.868/1.91 |

| 3×50+2×25 | 6/6 | 1.4/1.2 | 0.2 | 2.0 | 34.9 | 1560 | 0.641/1.20 |

| No. of Cores and Nominal Cross Section | Min. Number of Wires | Nominal Insulation Thickness | Nominal Steel Tape Thickness | Nominal Sheath Thickness | Approx. Overall Diameter | Approx. Weight | Max. D.C. Resistance of Conductor at 20℃ |

| No. × mm² | No. | mm | mm | mm | mm | kg/km | Ω/km |

| 3×70+2×35 | 12/6 | 1.4/1.2 | 0.5 | 2.2 | 40.0 | 2322 | 0.443/0.868 |

| 3×95+2×50 | 15/6 | 1.6/1.4 | 0.5 | 2.4 | 46.2 | 3000 | 0.320/0.641 |

| 3×120+2×70 | 15/12 | 1.6/1.4 | 0.5 | 2.5 | 50.3 | 3544 | 0.253/0.443 |

| 3×150+2×70 | 15/12 | 1.8/1.4 | 0.5 | 2.6 | 53.5 | 4016 | 0.206/0.443 |

| 3×185+2×95 | 30/15 | 2.0/1.6 | 0.5 | 2.8 | 59.9 | 4976 | 0.164/0.320 |

| 3×240+2×120 | 30/15 | 2.2/1.6 | 0.5 | 3.0 | 66.2 | 6050 | 0.125/0.253 |

| 3×300+2×150 | 30/15 | 2.4/1.8 | 0.5 | 3.2 | 72.9 | 7273 | 0.100/0.206 |

| 3×400+2×185 | 53/30 | 2.6/2.0 | 0.5 | 3.5 | 81.2 | 8975 | 0.0778/0.164 |

| 4×4+1×2.5 | 1/1 | 1.0/0.8 | 0.2 | 1.8 | 17.7 | 426 | 7.41/12.1 |

| 4×6+1×4 | 1/1 | 1.0/1.0 | 0.2 | 1.8 | 19.2 | 509 | 4.61/7.41 |

| 4×10+1×6 | 6/1 | 1.0/1.0 | 0.2 | 1.8 | 22.2 | 634 | 3.08/4.61 |

| 4×16+1×10 | 6/6 | 1.0/1.0 | 0.2 | 1.8 | 24.6 | 799 | 1.91/3.08 |

| 4×25+1×16 | 6/6 | 1.2/1.0 | 0.2 | 1.8 | 28.5 | 1072 | 1.20/1.91 |

| 4×35+1×16 | 6/6 | 1.2/1.0 | 0.2 | 1.9 | 30.9 | 1268 | 0.868/1.91 |

| 4×50+1×25 | 6/6 | 1.4/1.2 | 0.2 | 2.1 | 36.5 | 1699 | 0.641/1.20 |

| 4×70+1×35 | 12/6 | 1.4/1.2 | 0.5 | 2.3 | 41.9 | 2529 | 0.443/0.868 |

| 4×95+1×50 | 15/6 | 1.6/1.4 | 0.5 | 2.4 | 48.2 | 3257 | 0.320/0.641 |

| 4×120+1×70 | 15/12 | 1.6/1.4 | 0.5 | 2.6 | 52.4 | 3821 | 0.253/0.443 |

| 4×150+1×70 | 15/12 | 1.8/1.4 | 0.5 | 2.7 | 57.1 | 4514 | 0.206/0.443 |

| 4×185+1×95 | 30/15 | 2.0/1.6 | 0.5 | 2.9 | 63.0 | 5454 | 0.164/0.320 |

| 4×240+1×120 | 30/15 | 2.2/1.6 | 0.5 | 3.1 | 70.0 | 6707 | 0.125/0.253 |

| 4×300+1×150 | 30/15 | 2.4/1.8 | 0.5 | 3.3 | 77.4 | 8145 | 0.100/0.206 |

| 4×400+1×185 | 53/30 | 2.6/2.0 | 0.8 | 3.7 | 87.4 | 10858 | 0.0778/0.164 |

YOU MAY LIKE

Related products

-

Aluminum Conductor Products

AXMK Cable

-

Aluminum Conductor Products

YJLV Cable

-

Aluminum Conductor Products

U-1000 Ar2V Cable

-

Aluminum Conductor Products

AXMK PE Cable

-

Aluminum Conductor Products

E-AY2Y Cable

-

Aluminum Conductor Products

1-Ayky Cable

-

Aluminum Cable AL/XLPE/PVC 0.6/1KV

NA2XY -YJLV (AL/XLPE/PVC)

-

Aluminum Conductor Products

NA2XBY – YJLV22 (Al/XLPE/STA/PVC)