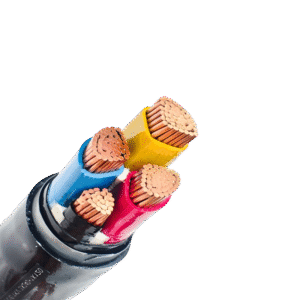

U-1000 RVFV XAV Cable

Power Cable 0,6/1 kV with Cu conductors, XLPE insulated and Double Steel Tape Armoured

Voltage Rating: 600/1000 Volts

Conductor: Copper conductor

Insulation: Cross-linked polyethylene (XLPE)

Out sheath: PVC

Armour: Double Galvansied Steel Tape

U-1000 RVFV XAV Cable Application

These U-1000 RVFV cables are suitable for direct burial without additional protection or for installation on cable trays or in ducts where mechanical protection is necessary

U-1000 RVFV XAV Cable Standard:

U-1000 RVFV XAV Cable Construction

Conductor: 1.5mm² to 4mm²: Class 1 solid copper conductor

6mm² and above: Class 2 stranded copper conductor

Class 2 stranded conductor available for these sizes on request

Insulation: Cross-linked polyethylene (XLPE) insulation type XLPE according to IEC 60502-1.

Armour: Double steel or aluminium tape armour. Aluminium armour is used in single-core cables to avoid parasite currents that may overheat the cable. Steel tape is used in the multicore cables.

Outer sheath: Flexible PVC outer sheath, Black colour.

The standard identification of insulated conductors is the following:

U-1000 RVFV XAV Cable Characteristics

| CROSS SECTION MM2 | INSULATION THICKNESS MM | AMOUR THICKNESS MM | MINIMUM SHEATH THICKNESS MM | MAXIMUM OVERALL DIAMETER MM | APPROX CABLE WEIGHT KG/KM |

| 2×1.5 | 0.7 | 0.2 | 1.3 | 11.5 | 230 |

| 2×2.5 | 0.7 | 0.2 | 1.3 | 12.5 | 275 |

| 2×4 | 0.7 | 0.2 | 1.4 | 13.5 | 330 |

| 2×6 | 0.7 | 0.2 | 1.4 | 15.5 | 430 |

| 2×10 | 0.7 | 0.2 | 1.4 | 16.5 | 555 |

| 2×16 | 0.7 | 0.2 | 1.5 | 19 | 770 |

| 2×25 | 0.9 | 0.2 | 1.6 | 22.5 | 1080 |

| 2×35 | 0.9 | 0.2 | 1.7 | 25 | 1390 |

| 3×1.5 | 0.7 | 0.2 | 1.3 | 12 | 255 |

| 3×2.5 | 0.7 | 0.2 | 1.3 | 13 | 305 |

| 3×4 | 0.7 | 0.2 | 1.4 | 14 | 380 |

| 3×6 | 0.7 | 0.2 | 1.4 | 16 | 500 |

| 3×10 | 0.7 | 0.2 | 1.5 | 17.5 | 665 |

| 3×16 | 0.7 | 0.2 | 1.5 | 20 | 930 |

| 3×25 | 0.9 | 0.2 | 1.6 | 24 | 1325 |

| 3×35 | 0.9 | 0.2 | 1.7 | 26.5 | 1720 |

| 3×50 | 0.9 | 0.2 | 1.8 | 29 | 2125 |

| 3×70 | 1.1 | 0.2 | 2 | 34.5 | 3080 |

| 3×95 | 1.1 | 0.5 | 2.1 | 40 | 4505 |

| 3×120 | 1.2 | 0.5 | 2.3 | 44.5 | 5540 |

| 3×150 | 1.4 | 0.5 | 2.4 | 48.5 | 6655 |

| 3×185 | 1.6 | 0.5 | 2.5 | 53.5 | 8150 |

| 3×240 | 1.7 | 0.5 | 2.7 | 61 | 10575 |

| 3×300 | 1.8 | 0.5 | 2.9 | 66.5 | 13055 |

| 3×50+35 | 1.0/09 | 0.2 | 1.9 | 33 | 2730 |

| 3×70+50 | 1.1/0.9 | 0.2 | 2 | 36 | 3440 |

| 3×95+50 | 1.1/1.0 | 0.5 | 2.2 | 42.5 | 5080 |

| 3×120+70 | 1.2/1.1 | 0.5 | 2.3 | 46.5 | 6275 |

| 3×150+70 | 1.4/1.1 | 0.5 | 2.5 | 50 | 7340 |

| 3×185+70 | 1.6/1.1 | 0.5 | 2.6 | 56 | 8975 |

| 3×240+95 | 1.7/1.1 | 0.5 | 2.8 | 62.5 | 11435 |

| 4×1.5 | 0.7 | 0.2 | 1.3 | 13 | 290 |

| 4×2.5 | 0.7 | 0.2 | 1.4 | 14 | 355 |

| 4×4 | 0.7 | 0.2 | 1.4 | 15 | 440 |

| 4×6 | 0.7 | 0.2 | 1.4 | 17 | 585 |

| 4×10 | 0.7 | 0.2 | 1.5 | 19 | 800 |

| 4×16 | 0.7 | 0.2 | 1.6 | 22 | 1120 |

| 4×25 | 0.9 | 0.2 | 1.7 | 26 | 1650 |

| 4×35 | 0.9 | 0.2 | 1.8 | 29 | 2135 |

| 4×50 | 1 | 0.2 | 1.9 | 32.5 | 2745 |

| 4×70 | 1.1 | 0.5 | 2.1 | 39 | 4295 |

| 4×95 | 1.1 | 0.5 | 2.3 | 44.5 | 5660 |

| 4×120 | 1.2 | 0.5 | 2.4 | 48.5 | 6880 |

| 4×150 | 1.4 | 0.5 | 2.6 | 53 | 8315 |

| 4×185 | 1.6 | 0.5 | 2.7 | 60.5 | 10510 |

| 4×240 | 1.7 | 0.5 | 2.9 | 67 | 13370 |

| 4×300 | 1.8 | 0.5 | 3.1 | 73 | 16360 |

YOU MAY LIKE

Related products

-

Steel Tape Armoured Cable Type

YJV22 Cable

-

Steel Tape Armoured Cable Type

NAYBY Cable

-

Steel Tape Armoured Cable Type

RVFAV-K Cable

-

Steel Tape Armoured Cable Type

RVFV-K Cable

-

Steel Tape Armoured Cable Type

X1AV Cable

-

Steel Tape Armoured Cable Type

LXAV Cable

-

Steel Tape Armoured Cable Type

ACYAbY ACYAbY-F Cable

-

Steel Tape Armoured Cable Type

N2XB2Y Cable